Spherical 3D Printing Tantalum Metal Powder for Medical

Spherical 3D Printing Tantalum (Ta) Metal Powder for 3D printing Products features The production process of PREP A) The;

Basic Info

| Model NO. | Ti-0013 |

| Oxygen Content | <150 Ppm;<300 Ppm; <500 Ppm |

| Feature | Corrosion Resistance |

| Colour | Silver Gray |

| Transport Package | Plastic Bag |

| Specification | 5kg/bag |

| Trademark | Guangzhou Sailong |

| Origin | Guangzhou |

| HS Code | 8103201100 |

| Production Capacity | 5000 Tons/Years |

Product Description

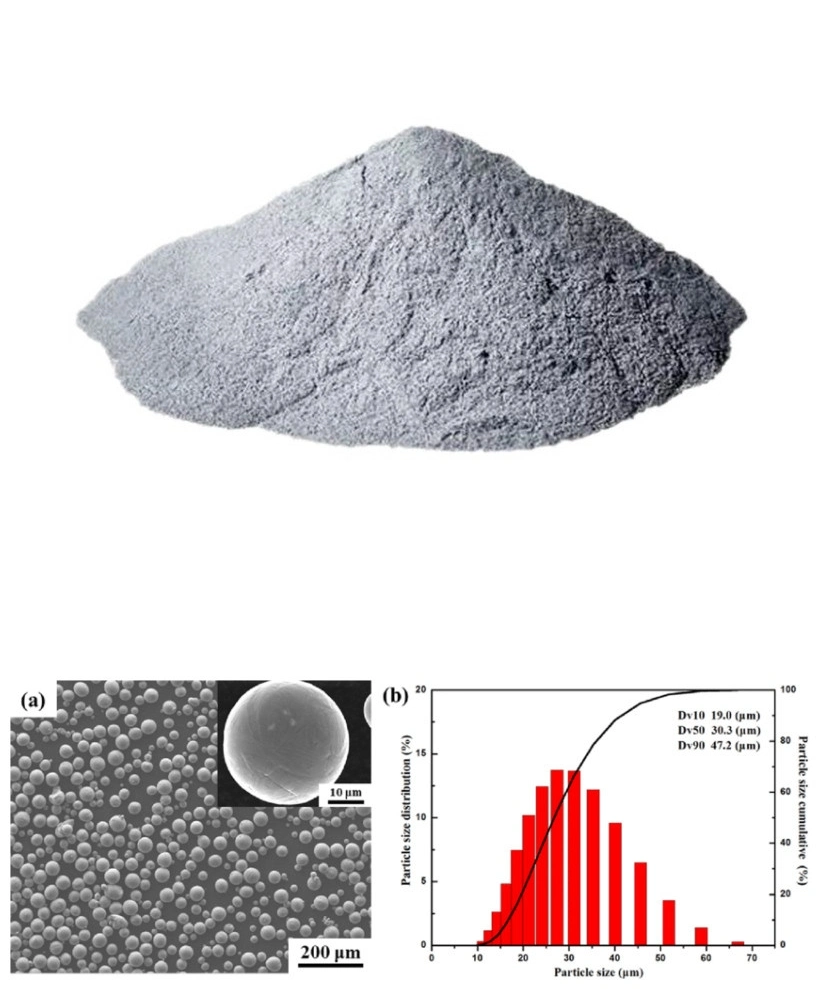

Spherical 3D Printing Tantalum (Ta) Metal Powder for 3D printingProducts features

| 1) Made by non-contact melting process; |

| 2) The powder has high sphericity, no hollow powder;narrow particle size distribution, good fluidity and strong density; |

| 3) The particle size range of Titanium Alloy Powders is 20-1000 μm; |

| 4) Effective control of powder particle size distribution; sphericity and oxygen consumption through optimized technology; |

| 5) Inert gas two steps treatment and compensation process can control the forming degree of EIGA producing atomizing alloy powder more efficiently; |

| 6) High purity spherical alloy powder with high sphericity, good fluidity and few non-metallic inclusions. |

The production process of PREP

A) The working speed of PREP is greatly increased, the powder sphericity has reached more than 95%, and the yield of fine powder has been significantly increased.B) The oxygen increment of active metals such as titanium alloy is controlled within 100ppm, while the oxygen increment of metals such as high-temperature alloys can reach 50ppm.C) The rod feeding of end surface is heated by plasma arc to melt into liquid.D) the liquid is ejected and crushed into fine droplets by the centrifugal force of high-speed rotation of the electrode.E) The droplets eventually form a spherical powder under the action of surface tension in the condensation process.

Applications

It is widely used in pigments, aerospace parts, automotive parts, marine parts, medical equipment and medical implants.

About us

Guangzhou sailong additives manufacturing co., ltd is a high-tech enterprise led by core members of the technical team. The company's entrepreneurial team is led by professor huiping Tang, million plan talent and director of the state key laboratory of porous metal materials, and Dr. qiangbing Wang, deputy director of the state key laboratory of porous metal materials. Professor Tang is the chairman of the company, and Dr. Wang is the general manager of the company. The company has more than 90% of the master.The company is mainly engaged in the design, development, production and sales of metal powder and additive manufacturing products, including 3d printing parts, powder metallurgy products, equipment manufacturing of refining and chemical production. Products have been widely used in aerospace, medical, petrochemical ,water treatment plant, metallurgy industry and other fields.

Certification

Shipping and service

Payment and service

QuestionsQ: Are you a trading company or manufacturer?

A: We are the professional manufacturer specializes in the development of porous metal filters for more than 20 years. We will always provide the best technical service support to our clients both in and after warranty period

Q: What materials are these products?

A: Titanium and titanium alloys, nickel and nickel alloys, stainless steel, or customized

Q:How long is your delivery time?

A: Generally it is 4-8 days if the goods are in stock. Production around 10-20 days , it is according to quantity

Q: What's your payment method ?

A: TT , L/C or Western Union

Q:Do you provide samples? is it free or extra?

A:Yes, we offer free samples, but freight charge on your side.

You may also like

Send inquiry

Send now