Polyolefin Heat Shrink Sleeving Tube

Polyolefin Heat Shrinkable Insulation Tube PHST series yellow&green shrinkable busing is processed and manufactured with;

Basic Info

| Model NO. | PHST |

| Raw Material | Polyolefin |

| Ratio | 2:1 |

| Colour | Black, Red, Yellow, Green, etc |

| Voltage | 600V |

| Initial Shrinking Temperature | 70c |

| Temperature | -50-125c |

| Fully Shrinking Temperature | 125c |

| Transport Package | Exporting Carton |

| Specification | ROHS |

| Trademark | Maxwel |

| Origin | Wenzhou |

| HS Code | 39173100 |

| Production Capacity | 10, 000 Meters/Day |

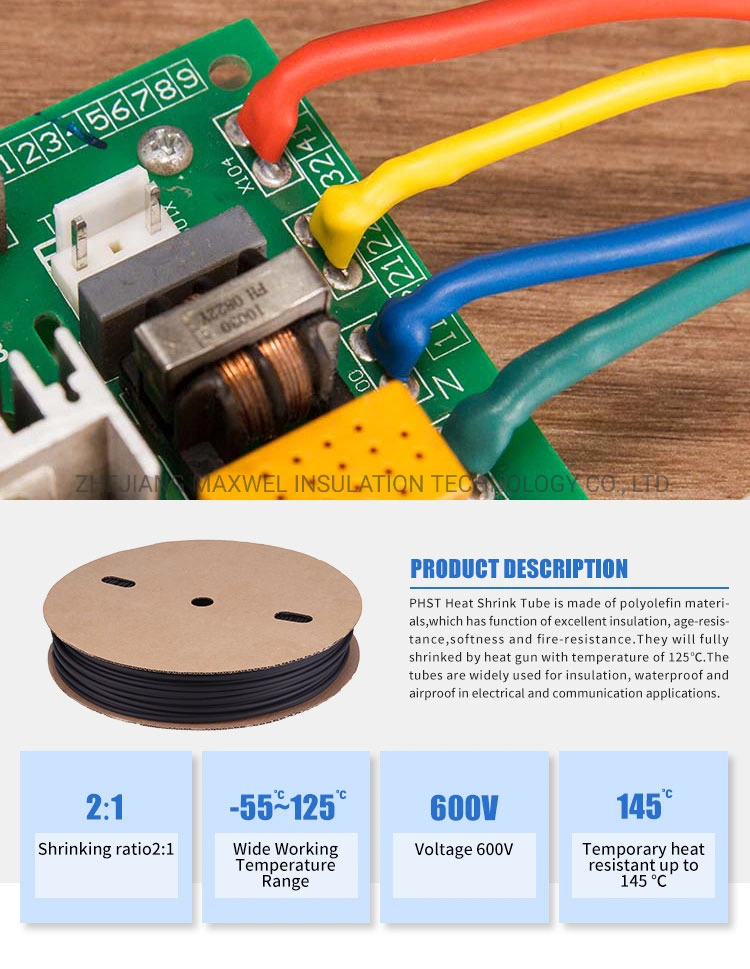

Product Description

Polyolefin Heat Shrinkable Insulation TubePHST series yellow&green shrinkable busing is processed and manufactured with excellent green and yellow polyolefin materials. When the products are shaped, they are cross linked and expanded continuously with electronic accelerator. The products are widely used in the marking of electric wires, earthing of cables, special lines and pipelines.

Features:

Application temperature: -50° C to 125° C

Initial shrinkable temperature: 70° C

Full shrinking temperature: 125° C

Softness, flame retardation, bright and durable colour, timely delivery and supply, convenient use, able to shrink when heated with oven or hot air gun

Standard colour: Yellow-green

Quality guarantee!

Surprising price!

| Size | Dimensio nbefore shrinking (mm) | Dimensio nafter shrinking (mm) | Standard packaging (m/disc) | Application (mm) | ||

| Internal diameter | Wall thickness | Maxinternal diameter | Wall thickness | |||

| 2.0 | 2.4 ± 0.3 | 0.25 ± 0.05 | 0.9 ± 0.1 | 0.35 ± 0.05 | 200 | 1.1~1.8 |

| 3.0 | 3.4 ± 0.4 | 0.25 ± 0.05 | 1.4 ± 0.1 | 0.40 ± 0.05 | 200 | 1.6~2.7 |

| 4.0 | 4.5 ± 0.4 | 0.25 ± 0.05 | 1.8 ± 0.1 | 0.45 ± 0.05 | 200 | 2.1~3.6 |

| 5.0 | 5.4 ± 0.4 | 0.25 ± 0.05 | 23 ± 0.1 | 0.55 ± 0.15 | 100 | 2.6~4.5 |

| 6.0 | 6.4 ± 0.4 | 0.28 ± 0.15 | 2.8 ± 0.2 | 0.55 ± 0.15 | 100 | 3.1~5.4 |

| 7.0 | 7.4 ± 0.4 | 0.28 ± 0.15 | 3.3 ± 0.2 | 0.55 ± 0.15 | 100 | 3.7~6.3 |

| 8.0 | 8.4 ± 0.5 | 0.28 ± 0.15 | 3.8 ± 0.2 | 0.55 ± 0.15 | 100 | 4.2~7.2 |

| 10 | 10.5 ± 0.5 | 0.30 ± 0.15 | 4.8 ± 0.2 | 0.55 ± 0.15 | 100 | 5.2~9.0 |

| 12 | 12.5 ± 0.5 | 0.30 ± 0.15 | 5.7 ± 0.3 | 0.60 ± 0.15 | 100 | 6.2~11 |

| 14 | 14.5 ± 0.5 | 0.35 ± 0.15 | 6.7 ± 0.3 | 0.60 ± 0.15 | 100 | 7.3~13 |

| 16 | 16.5 ± 0.6 | 0.38 ± 0.15 | 7.7 ± 0.3 | 0.65 ± 0.15 | 100 | 8.3~15 |

| 20 | 21.0 ± 0.8 | 0.40 ± 0.15 | 9.7 ± 0.3 | 0.75 ± 0.15 | 100 | 10.4~19 |

| 25 | 25.8 ± 0.8 | 0.45 ± 0.15 | 11.0 ± 1.0 | 0.75 ± 0.15 | 0 | 12.8~24 |

| 30 | 30.8 ± 0.8 | 0.45 ± 0.15 | 14.0 ± 1.0 | 0.75 ± 0.15 | 50 | 16~29 |

| 35 | 35.8 ± 0.8 | 0.50 ± 0.20 | 16.0 ± 1.0 | 0.85 ± 0.20 | 50 | 18~34 |

| 40 | 42.0 ± 1.0 | 0.50 ± 0.20 | 19.0 ± 1.0 | 0.85 ± 0.20 | 50 | 21~39 |

| 50 | 51.0 ± 1.0 | 0.50 ± 0.20 | 24.0 ± 1.0 | 0.85 ± 0.20 | 50 | 26~49 |

| 60 | 61.0 ± 1.0 | 0.65 ± 0.20 | 29.0 ± 1.0 | 0.85 ± 0.20 | 25 | 35~55 |

| 70 | 71.0 ± 1.0 | 0.65 ± 0.20 | 33.0 ± 2.0 | 1.00 ± 0.20 | 25 | 40~65 |

| 80 | 81.0 ± 1.0 | 0.65 ± 0.20 | 37.0 ± 2.0 | 1.00 ± 0.20 | 25 | 45~75 |

| 90 | 91.0 ± 1.0 | 0.65 ± 0.20 | 43.0 ± 2.0 | 1.00 ± 0.20 | 25 | 50~88 |

| 100 | 102.0 ± 2.0 | 0.65 ± 0.20 | 48.0 ± 2.0 | 1.00 ± 0.20 | 25 | 55~95 |

| 120 | 122.0 ± 2.0 | 0.80 ± 0.20 | 58.0 ± 2.0 | 1.50 ± 0.20 | 15 | 65~115 |

| 150 | 152.0 ± 2.0 | 0.80 ± 0.20 | 73.0 ± 2.0 | 1.50 ± 0.20 | 15 | 80~145 |

| 180 | 182.0 ± 2.0 | 0.80 ± 0.20 | 88.0 ± 2.0 | 1.50 ± 0.20 | 15 | 95~175 |

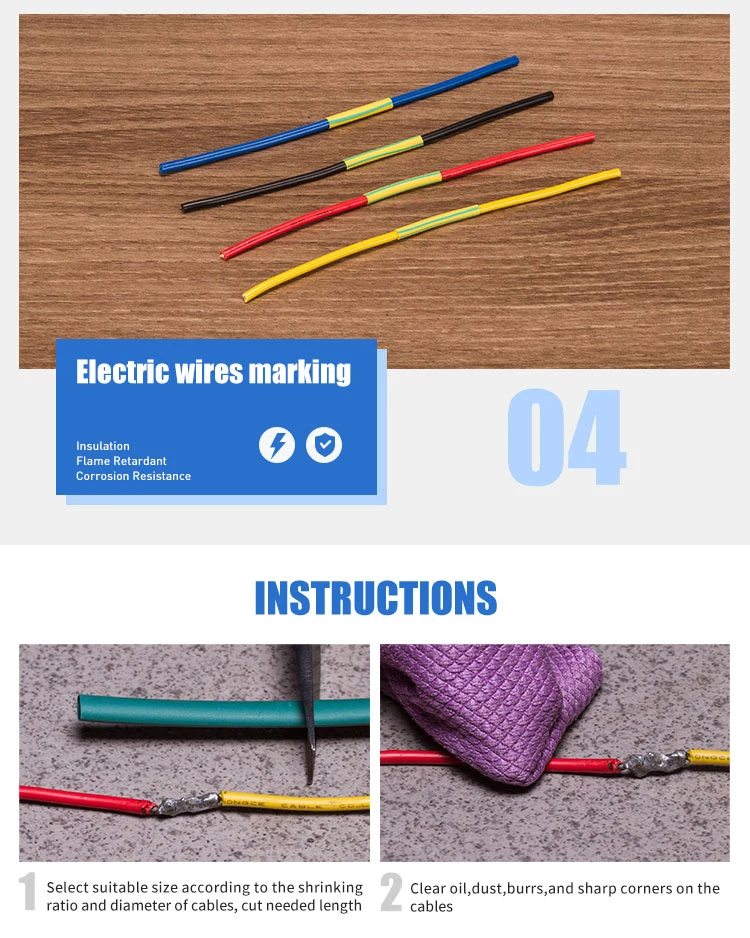

| wire coat and insulation |

| make the joint of terminal block and wire insulated |

| devide the colors |

| water-proof |

| protection and insualtion of insistors and electrical capacitors |

Features:

Shrink ratio: 2: 1

Operating temperature: -55 to 125 degree

Minimum fully recovery temperature: 110degree

Longitudinal shrinkage≤ 5%

Soft, Flammability, Environmental protection

The specification range from 1.0mm to 180mm, special specification is accepted.

Easy to operate, shrinking with the drying oven and the hot air gun

Standard color: Yellow and green Interaction

Pictures of heat shrink tubing :

You may also like

Send inquiry

Send now