High Quality Explosion-Proof Automatic Tank Gauge Atg Smart Console

Basic Info

| Model NO. | SS200a |

| Working Temperature | -20 To60ºC (-40 to 140f) |

| Display | 800*600, 8′′ Full Color LCD |

| Ex-Proof Grade | [Ex Ia Ga] Iia |

| Monitor Probes | up to 12 |

| Leak Sensor | Yes, 40 Max |

| Application | Gas Station |

| Transport Package | Cartons, Wooden Case |

| Specification | 320*270*420mm |

| Trademark | WINDBELL |

| Origin | Zhengzhou |

| HS Code | 902610000 |

| Production Capacity | 5000 |

Product Description

What are automatic fuel level gauge used for?

Automatic fuel level gauge are used for monitoring fuel liquid level, volume and temperature inside fuel storage tanks. It is widely used at gas station and skid-mounted fueling site. It also can be used at chemical factory, pharmacy industry and waste water tanks.

What can I benefit from automatic fuel level gauge system?

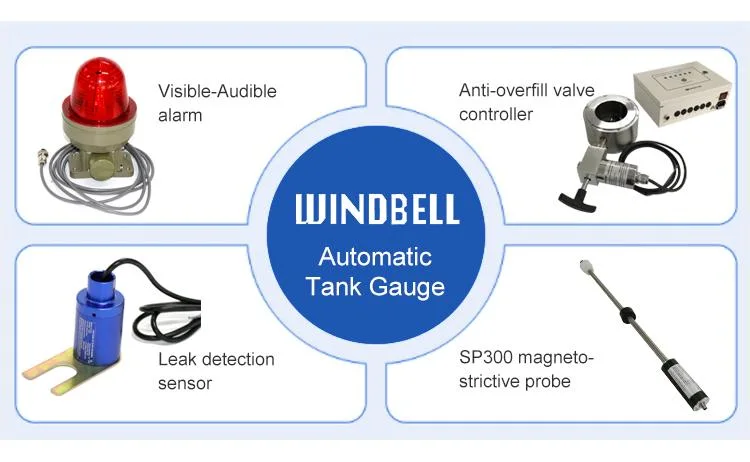

WB-SS200 smart tank gauge console integrates fuel management and environmental monitoring, and supports the access of magnetostrictive probes and a variety of sensors. With the console, can monitor fuel level, water level, temperature, inventory, alarm, leakage and other information of fuel tanks, and can generate various historical reports automatically.

WB-SS200 tank gauge console has two types, WB-SS200-A and WB-SS200-B. The WB-SS200-A has an 8-inch display and the WB-SS200-B has a 12-inch display.

Product Advantage- International graphical touch screen and user-friendly icons, easy to use.

- Monitor up to 32 tanks, and display fuel level, water level, volume, density and temperature for individual tanks.

- Monitor up to 64 leak detection sensors, which can be used for leak monitoring of tank interstice, pipe interstice, tank sump, dispenser sump and so on.

- Support multiple functional expansion, can simultaneously carry on level monitoring, leak detection, combustible gas detection, vapor recovery online monitoring, and static grounding detection.

- Support a variety of sensor types: float type, optical type, pressure type, liquid medium type and so on.

- Automatic sound-light alarm, support external sound-light alarm and voice alarm.

- Generates various reports, include delivery report, inventory report, alarm report, leak report and so on.

- Support tank table generation, correction, input, import and export.

- Support TCP/IP, remote data query on mobile and PC.

- Three-level security password management.

- Free switching between Chinese, English and other languages.

- Open networking protocol, which can be connected with the central control system of domestic mainstream petroleum equipment manufacturers, fully satisfying the petroleum company's demand for refined oil retail management.

- External GSM/GPRS module (optional).

- Built-in WIFI function (optional).

- Built-in printer (optional).

| Power | 90 ~ 264VAC/127 ~370VDC |

| Working temperature | -20 to 60ºC |

| Installation location | Safety zone |

| Display | WB-SS200-A: 8-inch color touch screen WB-SS200-B: 12-inch color touch screen |

| Ex-proof grade | [EX ia Ga] IIB |

| Safety barrier | -GSB05/GSB06/GSB-CL06 |

| Relay output | 2 groups. Node capacity AC250V/3A. DC30V/3A |

| External extension anti-overfill valve console | WB-DFV100-06A |

| External extension submersible pump console | SS160-EM02 |

| Output voltage | DC 12V |

| Monitor probes | Up to 32 |

| Leak sensor | Up to 64 |

| SMS module | Optional |

| GPRS module | Optional |

| Built-in printer | Optional |

| WIFI function | Optional |

| External sound-light alarm | Optional |

| External printer | Support |

| Running/Alarm indicator | Yes |

| Inventory and delivery management | Yes |

| Density and mass measurement | Yes |

| RS485 port | 1 |

| RS232 port | 2 |

| USB port | 1 |

| Ethernet port | 1, 100M |

| Buzzer alarm | Yes |

| Tank table | Yes, simulate/input/import/export |

| Reports | Inventory, delivery, shift, alarm, leak detection test, system log, SMS for optional |

| PC remote software | PCR200 |

| Anti-theft function | Yes |

| Dimension (L*W*H) | 360*280*110mm |