Fast Shipping Good Package Milk Tea Juice Beverage Filling Processing Machine for Food Industry

Basic Info

| After-sales Service | Provide 24-Hour Online Guidance to Solve Problems |

| Warranty | 12 Month |

| Condition | New |

| Customized | Customized |

| Voltage | Can Be Customized |

| Composition | Filtration Equipment |

| Processing Material | Natural Ingredients |

| Process | Thermal Processing |

| Application | Liquid, Herbal /Flower Essential Oil Extraction |

| Material | SUS304 or SUS316L |

| Heating Source | Steam/ Electric |

| Usage | Herbal Medicine/Tea/Leaves/Flower Oil/Food Additio |

| Power | Steam/Electric/Compressed Araw Materialir/Vacuum |

| Core Components | PLC, Motor |

| Key Selling Points | Low Noise Level, High Productivity |

| Working Temperature | High or Low Temperature |

| Solvent | Water or Ethanol or Other Organic Solvent |

| Feature | Easy-Operation |

| Output | Extractor Solution (Ointment )+ Residual Material |

| After Warranty Service | Online Support |

| After-Sales Service Provided | Online Support, Engineers Available to Service Mac |

| Key Selling Points1 | Security |

| Key Selling Points2 | Aseptic Filling |

| Transport Package | Standard Export Wooden Case |

| Specification | BD-AE-P |

| Trademark | BIOGREEN |

| Origin | Wuxi, Jiangsu |

| Production Capacity | 1000PCS/Month |

Product Description

Extract products:

This Extraction Equipment Line suits for extraction of herbal material, such as rose oil, zedoary turmeric oil, staranise oil, litseacubeba oil, patchouli oil, peppermint oil, lavender oil, herbal extarction, and beverage extraction.

Hemp extraction , Oat milk processing Pineapple stem protease. It is easy for operating and withhigh oil extraction rate. It meets for GMP standard.

Application industry:

It is suitable for traditional Chinese medicine, plant, animal, food and chemical industries, such as normalpressure and pressure water decoction, warm extraction, heat reflux, forced circulation, percolation, aromatic oilextraction and organic solvent recovery process, especially the dynamic extraction or countercurrent extractioneffect is better, short time, high concentration.

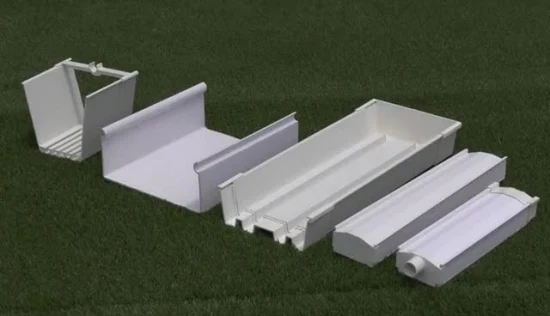

Components:

The extraction agitating tank is composed of an extractor, defoaming device, condenser, cooler, oil-waterseparator, agitator, material pump, filter, valve and pipeline.

The main body of the extraction agitating tank consists of an inner cylinder, a jacket layer, a heat insulating layer,a branch ear, apneumatic slag discharging gate, and a heat insulating layer of the extracting tank,and thealuminum silicate rock wool is used as the heat insulating material, the inner cylinder body is SUS304/316L.The tank is equipped with CIP cleaning ball, thermometer, explosion-proof sight lamp, quick opening feedgate, etc..

Characteristics:

1. The slag door structure adopts closed cylinder slag door,there are two cylinder pushing turn solid rotationaside, thread structure which make its multi wedge block drive the door lock up slag, slag door and tank flangeplaten close and seal well, with high safety factor.

2. Material discharget pipe adopts stainless steel pipe, liquid outlet joint is sealed reliably, avoiding the fatiguestress of the metal hose and affecting the frequent breakage and leakage.

3. Complying with (GMP) standard requirements.

Model | BD-10 | BD-20 | BD-30 | BD-50 | BD-100 | BD-200 | BD-300 | BD-500 | BD-1000 |

Volume | 10 | 20 | 30 | 50 | 100 | 200 | 300 | 500 | 1000 |

Material | Stainless steel 304 / 316 / high borosilicate | ||||||||

Stirring power | 200W | 370W | 370W | 550W | 1100W | 3000W | |||

Condensation system | Tube condenser + coil cooler | ||||||||

Concentration method | Single effect concentration / vacuum concentration tank / ball concentrator / scraper concentration | ||||||||

heating method | Electric heating | Electric / steam heating | Steam heating | ||||||

Vacuum | -0.03~0.09 | ||||||||

Steam consumption | 0 | 18KG/H | 35KG/H | 70KG/H | 120KG/H | 200KG/H | 250KG/H | ||

Expandable function | Organic solvent explosion-proof extraction, Soxhlet extraction, ultrasonic extraction, valve automation, automatic pin bubble function, online concentration detection function | ||||||||

Stainless Steel Dynamic Extractor Residue Discharging Door

1 Rapid open safety type residue discharging door

The tank cover can be automatically opened and closed. It adopts three-cylinder control and is provided withsafety device to avoid accidental operation and provide high safety factor. It is suitable for use in small andmedium-size reside discharging vent.

2 Rotary type residue discharging door

The tank cover can be automatically opened and closed. High temperature and high pressure extraction can beachieved in the swivel type product. It provides more selection for extracting technology. It can also meet somespecial technological requirements. With good safety guarantee functions and the extracting tank has no leakage.

3 Large-diameter residue discharging door

The tank cover can be automatically opened and closed. High temperature and high pressure extraction can berealized to provide more selection for extracting technology. With high safety factor, the residue discharging dooris suitable for residue discharging of large-diameter upside-down type extracting tank.

4 Another option of liquid discharging in the extraction agitating tank

(1) The filter board at the bottom of the extracting tank is made of two layers. The first layer is a 5-6mm thickstainless steel sheet with a thickness of 0.6mm thick is at the top of this supporting layer, and long holes of0.5*10mm are spread over the stainless steel sheet. The long holes are comparably not easy to be blocked.

(2) According to material requirements of customers ,the filter barrel is installed on the internal bladder or theextracting tank. Vertical grain type filter screen can be adopted. The filtering area of the filter barrel is several timeshigher than the bottom area, which can solve the problem of blocking and difficult liquid discharging at the bottomof the extracting tank.